Production Management System (SGP)

A management system can help to center, organize and systematize processes for management and improvement. Often, we don't know how to do it better; things are as they are and we have learned to live with it. Production machines are designed from the base of a certain production capacity. In practice, and for different reasons, production always lags far behind the capacity that was installed. In addition, it seems that the improvements implemented have little effect on productivity. At higher production speeds, more products are rejected; and when we focus more on quality, the machine does not work as it should.

A management system can help to center, organize and systematize processes for management and improvement. Any business activity involves managing a significant amount of information. Therefore, it is of major importance to store and, above all, structure data in an informatic system, which will allow, among other benefits, a better level of access to it and an improvement in efficiency levels.

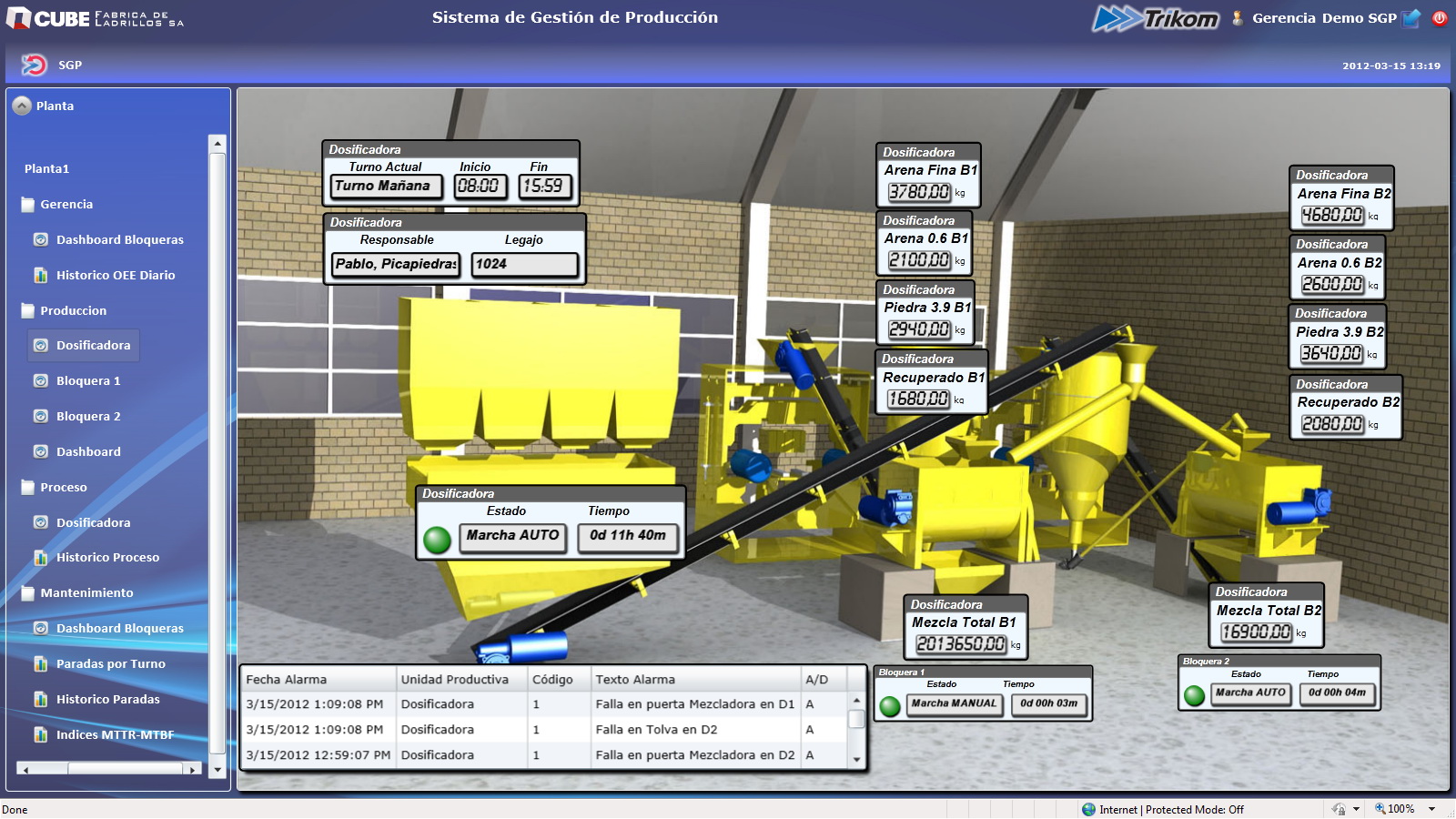

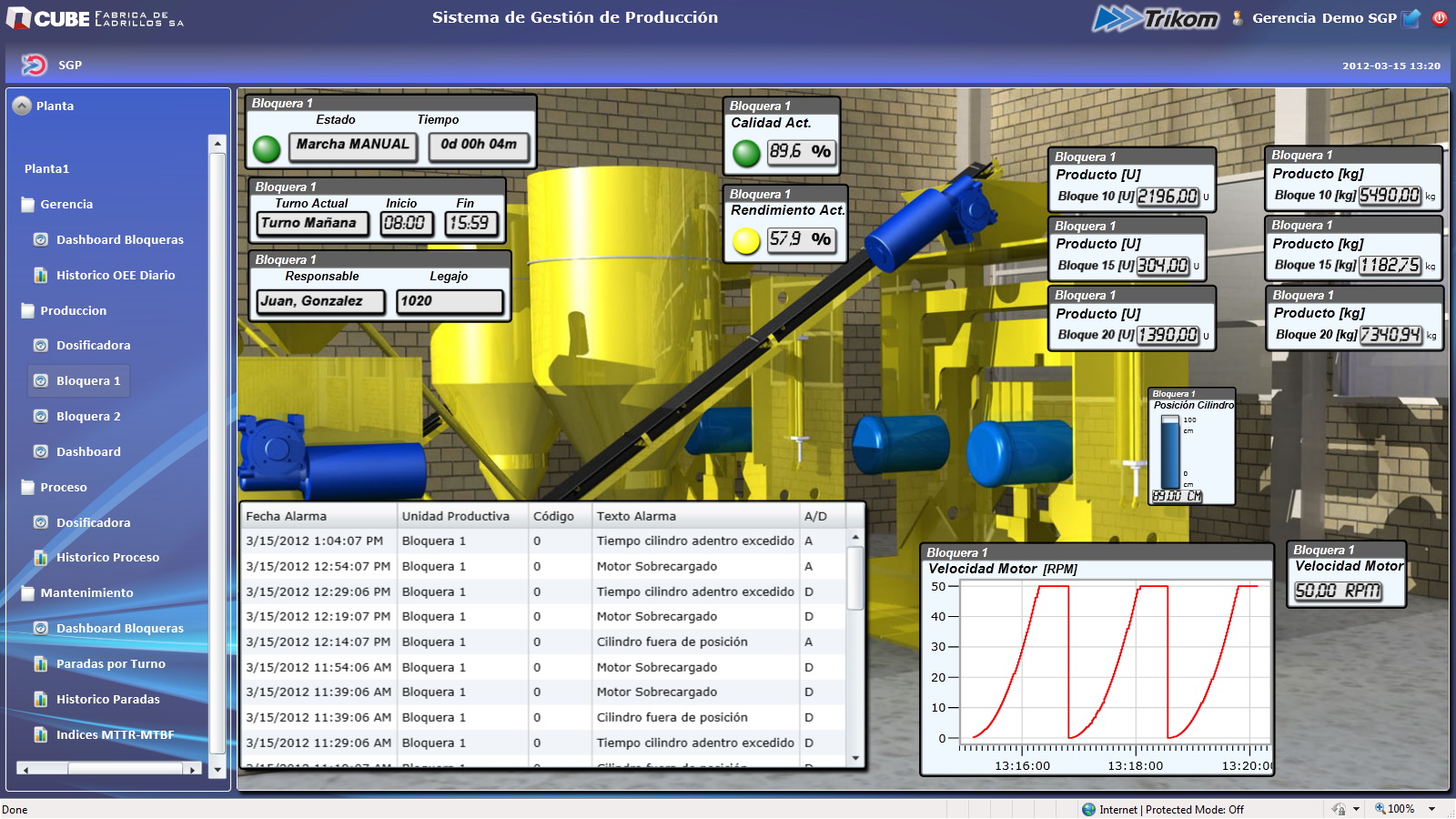

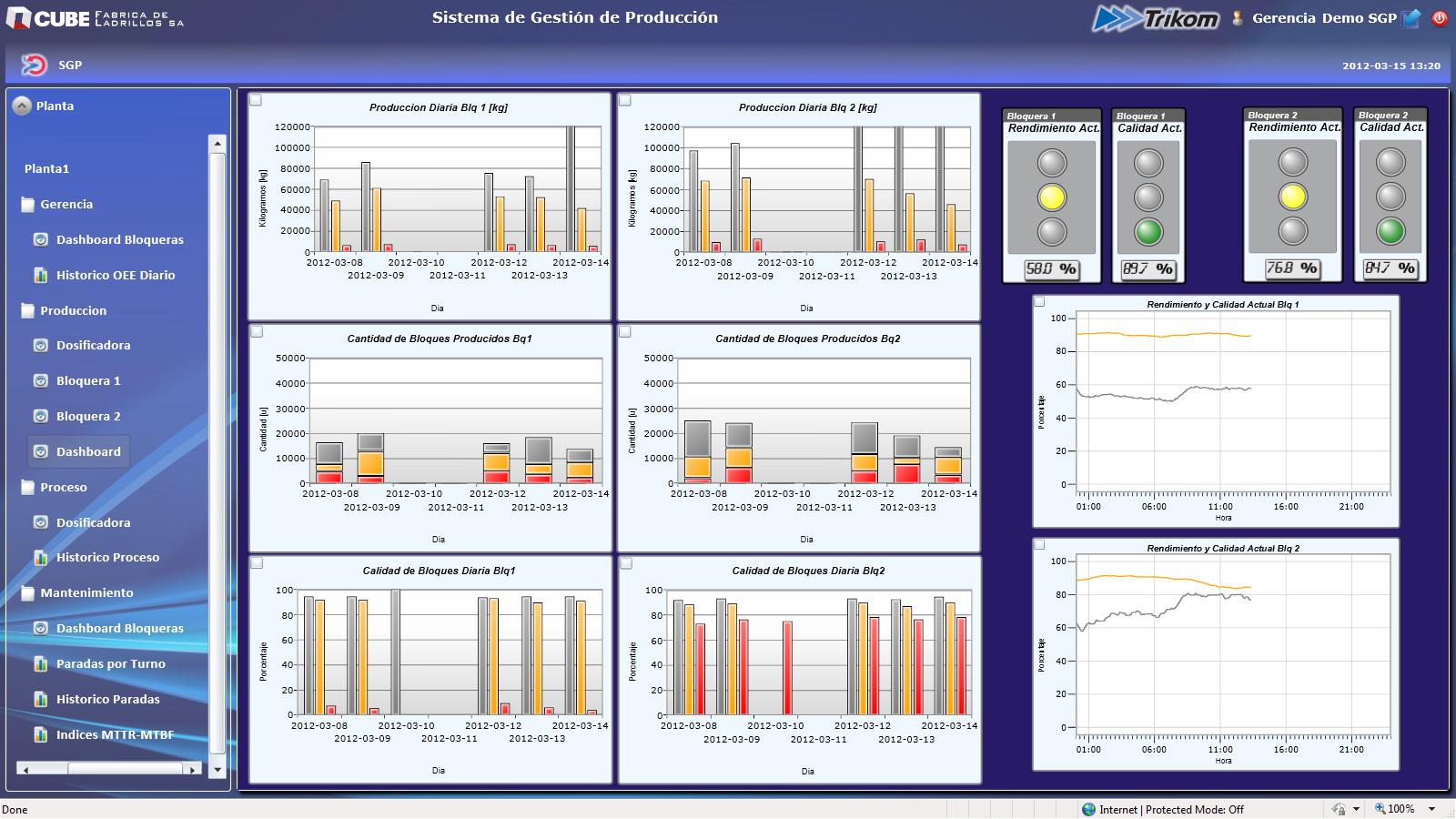

The GSP, pursues this objective based on data obtained directly from the plant, which guarantees real and useful information for decision making.

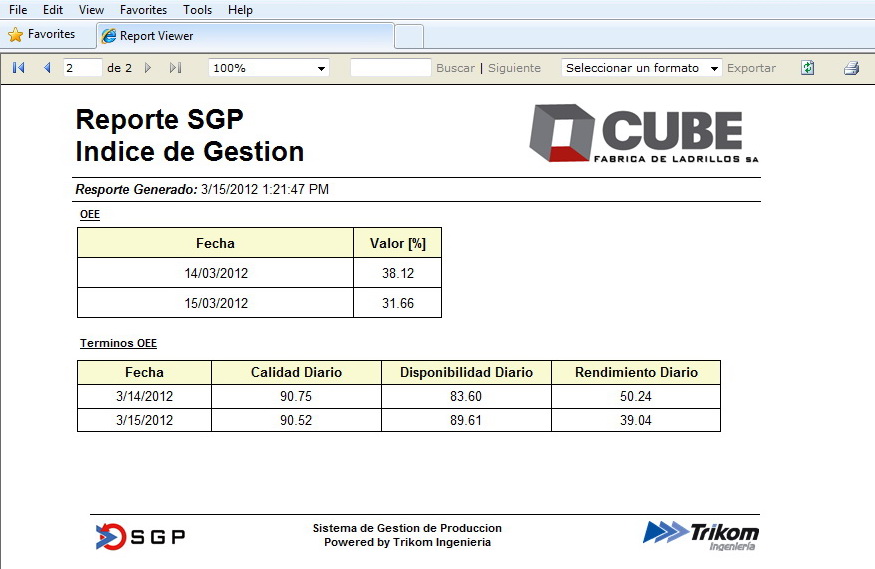

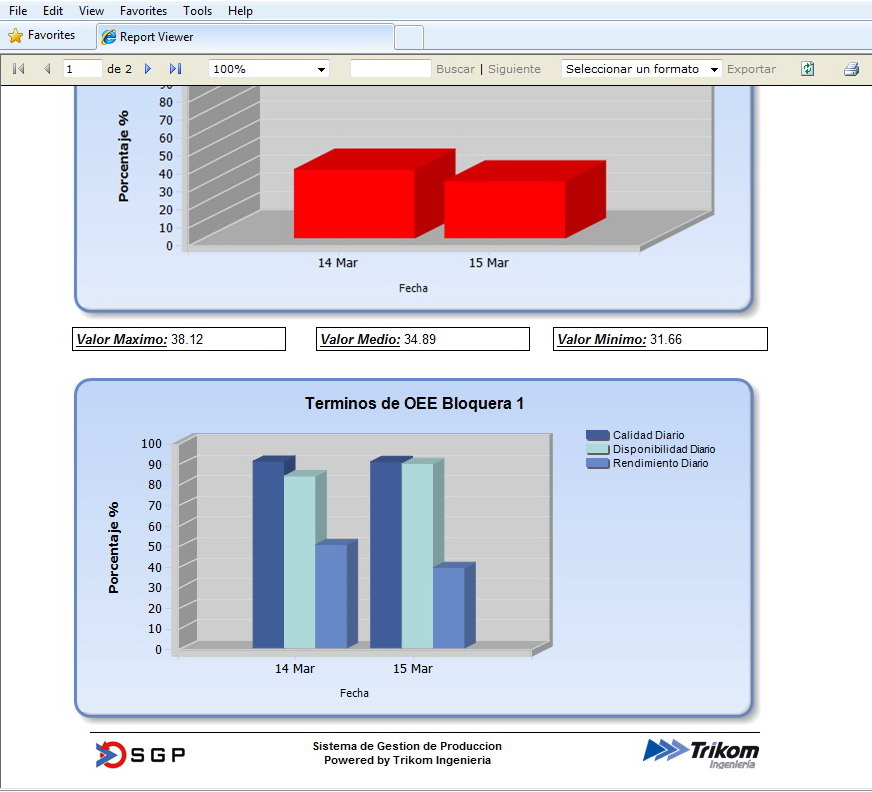

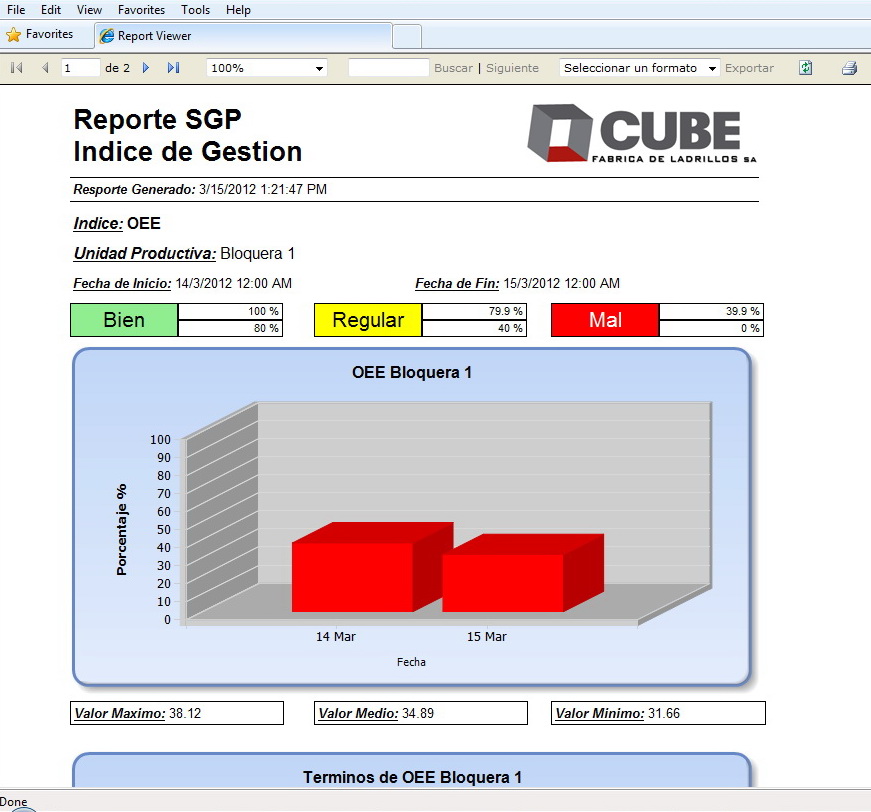

The system will help you to identify hidden losses that result in low productivity. You can improve productivity by understanding these losses and eliminating the root cause of each of them. It is based on the three fundamental pillars of the OEE (Overall Equipment Effectiveness):

- Availability: How long has the machine been running compared to the time you wanted it to be working?

- Use: During the time it has been running, how much has it produced regarding to how much should has it produced at the ideal cycle time?

- Quality: How many products in good condition have been made regarding to the total production carried out?

Benefits

The automation of business processes is undoubtedly one of the greatest benefits that informatics has brought to the field of industry. Not only does it speed up processes, with the consequent cost savings and increased efficiency, but it also becomes an essential basis for increasing the competitive advantages of companies and to go through growth stages.

This tool will start a process of continuous improvement in your company:

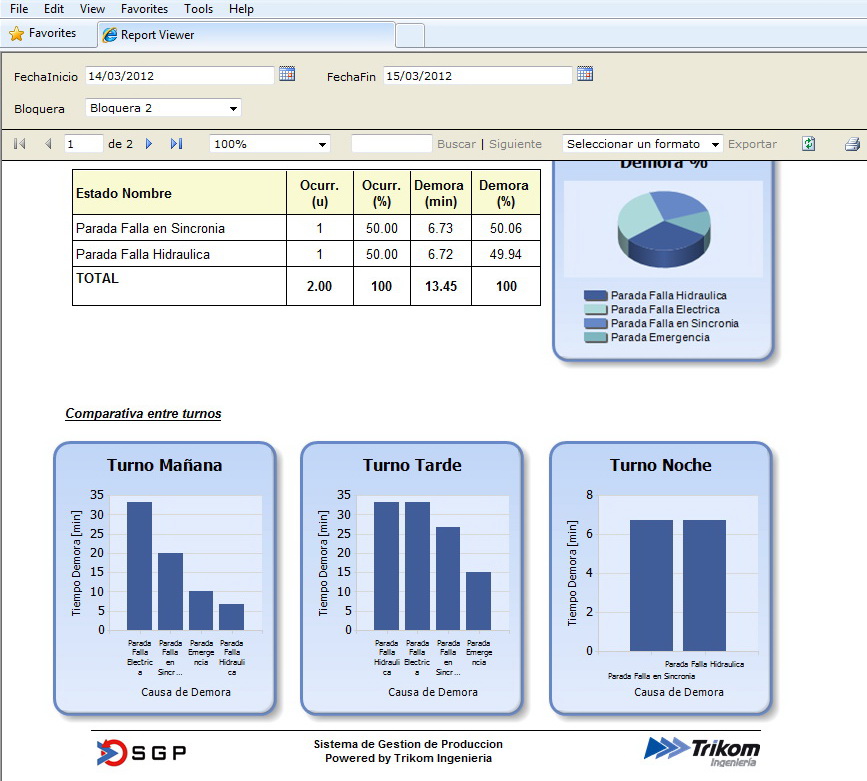

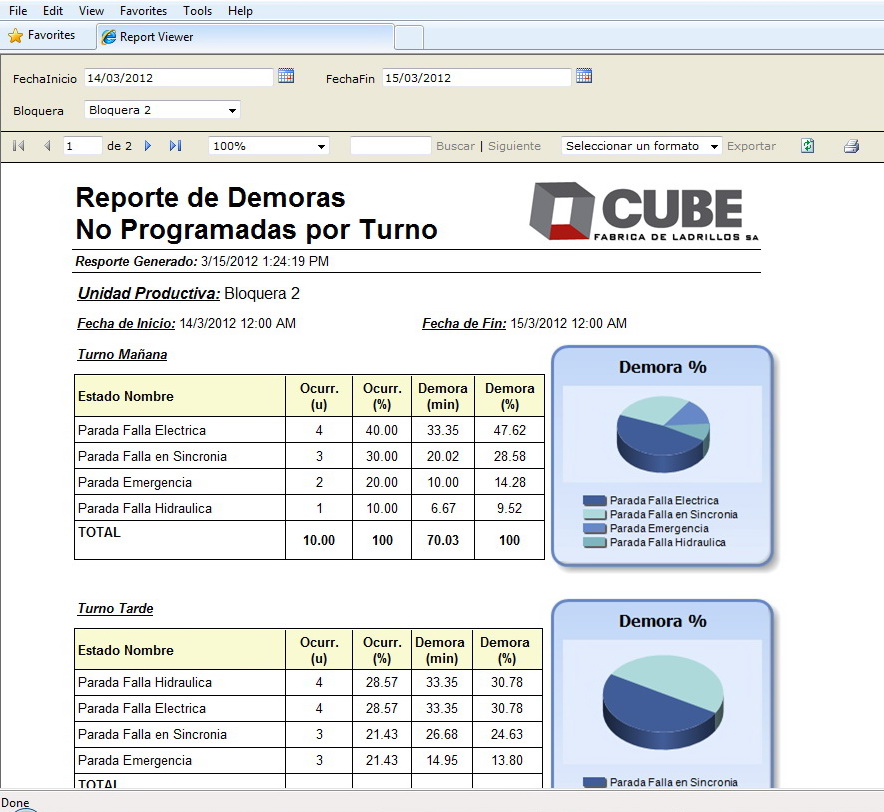

- It is infallible to clearly indicate where the problem is.

- Show priorities in a very clear way.

- You will be able to correctly select the specific improvements required.

- The results of the improvement actions undertaken are quickly observed.

- Contains reports and simple and easy indicators to understand for all those involved (KPIs, Failures, Gantt and Variable Trendings).

TRIKOM

follow us

contact

Argentina Headquarters

Pres. Hipólito Yrigoyen 3469, Florida (B1604DID)

Buenos Aires - Argentina